Last Updated on March 12, 2022 by

Imagine a room full of chocolate lovers, smelling, swirling and tasting delicious chocolates. While wine tasting is extremely popular, chocolate tasting in India is a new concept. While virtual chocolate tasting is popular, I am glad I could attend an event physically in Ahmedabad. Chocolate tasting in Ahmedabad is here all thanks to the effort of a chocolatier.

A few weeks ago I took part in a chocolate tasting session in Ahmedabad. This was the first of its kind event to have ever happened in Ahmedabad and I was elated to participate in this.

Table of Contents

Chocolate Tasting in Ahmedabad – The workshop

While everyone loves chocolates, very few can actually differentiate between the types of chocolates. This workshop was an extremely immersive and sensory experience that demonstrated the difference between compound chocolates and pure artisans chocolates. A brief history of chocolates, followed by purity engulfed everyone in the session.

The chocolatier explained the bean to bar process and everything in between the raw material extraction process of cacao beans to the tempering which brings chocolate in its truest forms. The 90-minute session also included how the chocolates are made, the difference between industrial and micro-batch chocolate production and pure and compound chocolates. It was followed by a slow sensory tasting of about 15 different types of compound and fine quality single-origin chocolates with various flavours such as fruity, flowery, spicy, nutty, earthy, etc.

History of Chocolate

Whenever we hear chocolate, we invariably think of a Cadbury bar. Although newer fancier chocolates are available in the market, one always goes back to the childhood memory of tasting it for the first time.

Did you know that chocolate refers to anything made from cacao beans?

Etymologists trace the origin of the word “chocolate” to the Aztec word “xocoatl,” which referred to a bitter drink brewed from cacao beans. The Latin name for the cacao tree is Theobroma cacao, which means “food of the gods.”

The earliest linguistic evidence of chocolate consumption stretches back three or even four millennia, to pre-Columbian cultures of Mesoamerica such as the Olmec. Both the Mayans and Aztecs believed the cacao bean had magical, or even divine, properties, suitable for use in the most sacred rituals of birth, marriage and death.

Origin of Chocolate

Chocolate’s history began in ancient Mesoamerica, present-day Mexico. The cacao plants were found here first, 4000 years ago. The Olmec, one of the earliest civilizations in Latin America, were the first to turn the cacao plant into chocolate.

Although cocoa originated in the Americas, West African countries, particularly Côte d’Ivoire and Ghana, are the leading producers of cocoa in the 21st century, accounting for some 60% of the world cocoa supply.

Did you know Cacao beans are grown in India?

Cocoa is grown primarily as an intercrop in Andhra, Tamil Nadu, Karnataka and Kerala. Malabar Forest Single Origin Dark Chocolates are quite popular in India and have faithful takers across the country.

Types of Cacao Beans

There are three varietal types in cocoa namely Criollo, Forastero and Trinitario. Criollo and Trinitario are the fine varieties prized for making chocolates with the most interesting and complex flavours. Forastero is typically the hardier, more reliable strain and has a higher yield of cacao pods. As a result, it’s easier and cheaper to grow, which is why it is generally used to make mass-produced chocolate. Forastero types are known to perform well under Indian conditions.

Bean to Bar Process

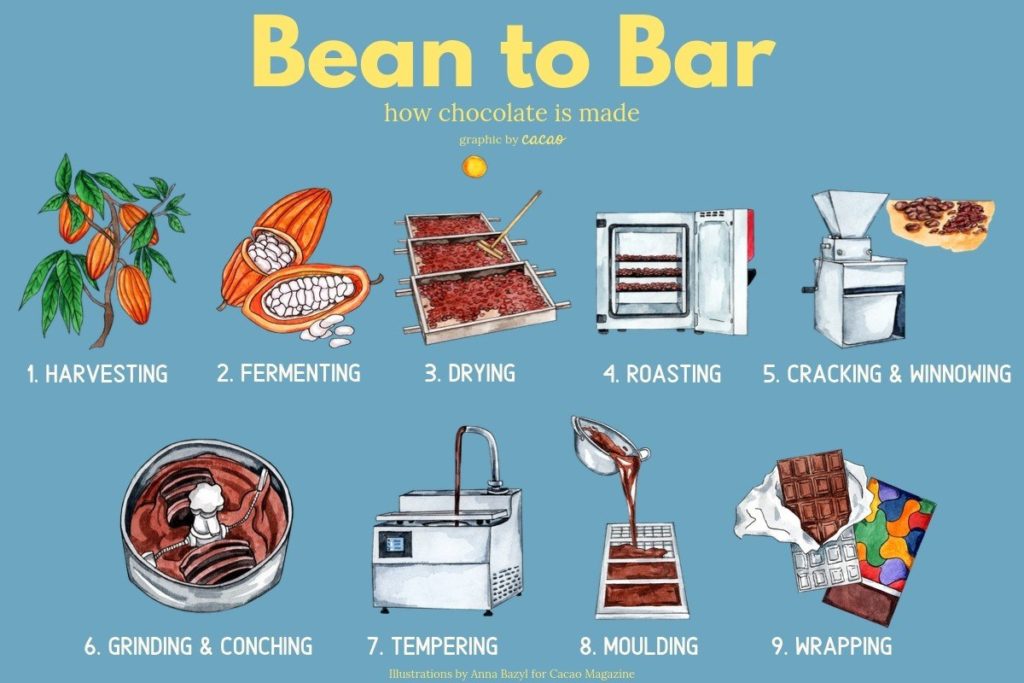

These are the 9 steps that take the humble cacao bean to a chocolate bar:

Harvesting

The cacao fruit that grows on the cacao tree is known as the cacao pod, which grows on the trunk and branches. Each pod ripens at a different time, which is harvested by a local expert.

Fermentation

Each pod that contains 30 to 40 seeds is cut open. The fibrous white pulp that surrounds each seed begins to ferment when exposed to the air. The pulp covered seeds are scooped out and fermented in big banana leaves or boxes with holes to allow the sticky white liquid to escape. The beans are mixed or turned to enable this process and the temperature naturally rises to 40-50°C.

Drying

In order to remove the high moisture content, after fermentation, the beans are dried. Usually, it is air-dried but in humidity prone areas, drying also takes place by using open fires.

Once dried, the beans are then sorted and bagged, before being shipped to makers around the world.

Roasting

The roasting process is done by chocolate makers and the length of time and temperature the beans are roasted depends on the type of quality of the bean. Roasting is important for getting rid of any bacteria in the bean.

Cracking & Winnowing

After the roasting process, the cacao beans are left with a dry and brittle outer shell, the beans are then cracked (by hand or by machine) and the shell is removed by a process called winnowing. The shells are blown away by fans leaving behind pure cacao bean pieces, known as “nibs”.

Grinding & Conching

For this process, two giant revolving granite rollers on top of a revolving granite slab are used. It converts the nibs into a cocoa mass which consists of cocoa solids and butter. During conching, some chocolate makers add extra ingredients e.g. sugar, milk, vanilla depending on what the final product is.

The conching process can take a few hours or a few days and has a big impact on the texture and taste of the final product. Deciding how long to conch for is down to the experience and skill of the chocolate maker.

Tempering

This is the process of raising and lowering the temperature of the chocolate so that it is formed into the right consistency through the treatment of the crystals. Without tempering, the chocolate would be dull and crumbly, missing the tempting shine and recognisable snap of a finished chocolate bar. This is traditionally done by hand but the process can also be sped up with a tempering machine.

Moulding

Once tempered, the melted chocolate is poured into the chosen mould and tapped against a hard surface to remove air bubbles. Craft chocolate-makers often do this by hand, while for larger manufacturers the process is mechanized for efficiency.

Wrapping

After the chocolate has cooled and solidified it is inspected for quality control. The final bar is then carefully wrapped in foil or paper packaging to keep it fresh and labelled for supplying to the shop or market to be consumed by chocolate lovers.

Chocolate Tasting in Ahmedabad – The Session

Since all the participants were now well versed with the history, origin and bean to bar process of the chocolate, we moved on to the next session – Chocolate Tasting Session. We were given a paper sheet with a list of flavours and were trained to taste chocolate.

- Take a sniff and try to guess the flavor

- Snap the chocolate

- Swirl the chocolate in such a sway that it melts with saliva and not break with teeth

- Before moving on to the next chocolate, smell coffee beans and drink warm water to negate the flavour and the aroma of previous chocolate.

We were ready for our sensory chocolate experience.

With every bar of chocolate, we were astounded by the aroma, the texture, the famous, the snap and the after taste. It was a rewarding and enriching experience knowing the source of every chocolate. From compound chocolates to fine artisan chocolates, we tasted about 15 varieties of chocolates and understood the process that brings chocolate in its truest forms.

What is Artisan Chocolate?

Only during the workshop did we truly understand the meaning of artisan chocolate and what goes behind making them.

Artisan chocolate means the chocolate produced by small chocolate makers who are nothing less than artisans, who understand and create their craft intimately. Artisan Chocolate making is an intimate process made by hand and in small batches, which means it is fresh and mindfully crafted. This results in a variety of interesting aromas and flavours that you won’t find in the mass-produced chocolates by brands.

Fine chocolate is fast becoming as sophisticated as wine. The chocolate tasting workshop was an extremely immersive and sensory experience that demonstrated the difference between compound chocolates and pure artisans chocolates.

Recommended Read: Wine Tasting at Sula Vineyards

Artisan Chocolate Ahmedabad | Chocolate shop in Ahmedabad

If you are already drooling with chocolate filled eyes and wondering where you can get artisan chocolate in Ahmedabad or if a chocolate shop in Ahmedabad can deliver it to you then yes your prayers are answered.

Bulk orders, corporate orders, festive orders or special orders are taken here! Address below (scroll down).

Will such Chocolate Tasting Workshops in Ahmedabad happen regularly in future?

Yes! There are plans to regularly have such chocolate workshops where chocolate lovers can have a sensory experience of understanding their chocolates.

Fine Artisan Chocolate Ahmedabad

Contact: Cacao Entice

Name of Founder: Ms Harnish Kaur

Address: Cacao Entice, Silver Cloud Hotel, Opp. Gandhi Ashram & Dandi Bridge, Hridaya Kunj, Old Wadaj, Ahmedabad

For orders, contact: +91 7600087016

Instagram: @cacaoentice

More posts on Cafe’s of Ahmedabad:

Disclosure – I was invited by Cacao Entice for the Chocolate Tasting Session. However, all opinions in this post are unbiased and of my own.

Disclaimer – This post may contain affiliate links. It means it adds no extra cost to you if you book through the link but I get a referral bonus which helps me earn a little to keep this website up and running.

1 comment

Love this! I have always wanted to do an official chocolate tasting!